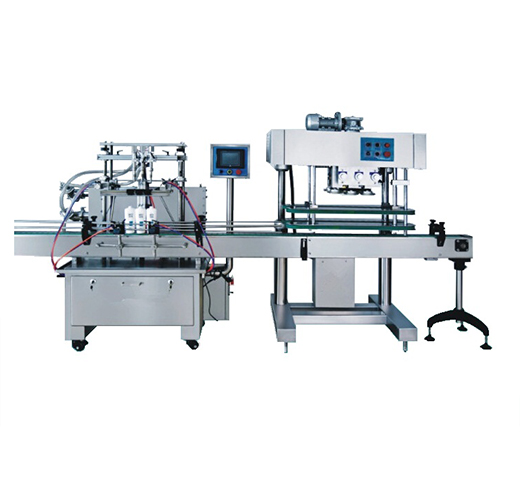

JF Automatic filling and capping machine

product Introduction

Paste/liquid filling production line is the introduction of absorbing the advanced technology developed and become a new generation of fully automatic filling machine. Equipment set light, electricity, gas and PLC microcomputer control into an organic whole, from put the action such as orientation, filling, capping,the bottles are completed fully automatic. Using linear/disc structure, special metering pump, quantitative measurement precision, finished product less waste. Reasonable design, compact structure, beautiful shape, with stable and reliable performance, high filling precision, strong adaptability, simple operation and convenient maintenance, etc. Used in different viscosity of water filling and cream products, widely used chemical, food, pharmaceutical, oil and other industries.

Performance characteristics

1, the use of the world's famous brands electrical and pneumatic components, low failure rate, stable and reliable performance, long service life;

2, contact with the material is 304 or 316 l stainless steel, corrosion resistance, acid and alkali resistance, tear open outfit is simple, easy to clean and conform to the hygiene requirements;

3, filling volume and filling speed adjustment, simple intelligent photoelectric sensor, a bottle filling machine, no bottle no filling, charging liquid level automatic control, convenient, fast, save the human;

4, equipment, good compatibility, no replacement parts, replacement of different specifications of the bottle shape can be changed very fast, can meet many varieties, specifications of the production requirements;

5, filling the mouth with drip tight device, ensure filling without drawing, no dripping.

6, filling production line machine sealing operation, in line with the GMP standard.

7, production lines, smooth operation, easy to each function combination, easy maintenance, can according to user's respective production process requirement for a variety of combinations.

8, the filling speed is: how fast a two-speed filling, filling speed is adjustable, prevent overflow bottle phenomenon

9, Siemens true color human-machine interface, man-machine interface respectively set parameters, working status and help information, fault alarm functions, simple intuitive; Greatly convenient for the adjustment of the parameters and the test functions;

Technical parameters

| Model | JF |

| Filling volume | 5ml-5,000ml(customized) |

| Filling speed | customized |

| Filling type | piston/scoop filling machine |

| Filling head | 2,4,6,8,10,12,14,16,18,20,22,24 pcs |

| Filling accuracy | 《±1% |

| control panel | PLC |

| Machine material | SUS304/SUS316L |

| Device driver | Cylinder, servo, hydraulic (optional) |

| Packaging containers | Bottles, barrels, cans, cups and other containers |

| Applicable materials | Fluid, liquid, cream, sauces and other fluid and semi-fluid |

Note: In case of nonconformity of the data in the table due to technical improvement or customization, the real objects shall prevail.

Products related to this product / Related Products

- JF-A Vacuum Homogenizer Mixer (Hydraulic Lifting)

- JF-A vacuum emulsifier is professionally designed according to the ointment manufacturing process of cosmetics and ointments etc. Products through introducing advanced technology from abroad. The machine unit is composed of pretreating boiler, vacuum emulsifying and blending boiler , vacuum pump. Hydraulic system, dumping system , electric control system and work platform etc.

- JF-A Small Laboratory Emulsifier

- Small vacuum homogeneous emulsifying machine is suitable for various type of ointment, honey products, small, pilot or a board, it is the cosmetics, pharmaceutical production enterprises laboratory indispensable experimental tool. Equipment has complete function, reliable quality.

- JF-B Emulsion Machine (Fixed type)

- Vacuum homogeneous emulsifying machine is a set of mixing, dispersion, emulsification and homogenization, powder absorbing functions in one integrated system, a control system, but also with the peripheral oil, water tanks, the use of vacuum, heating / cooling system. Is a special equipment for producing medicinal ointment, cream, lotion and other high-grade.

Manufacturing Equipment

- Emulsifying Machine

- Liquid Washing Homogenizer Mixer

- RO Water Treatment Machine

- Perfume Making Machine

- Homogenizer & Dispenser

- Grinding Machine & Mixing Machine

- Laundry Equipment

Packing Equipment

- Automatic Filling and Capping Machine

- Aerosol Equipment

- Hand-made Soap Equipment

- Labeling Machine

- Capping Machine

- Sachet Packing Machine

- Sealing Machine

- Shrink Packing Machine