Jinfeng analyzes the Emulsifying Machine for you

The use of Emulsifying Machine is more extensive, the equipment in the sunscreen, shower gel and so on a lot of cream products used in the food industry is mainly used for sauce, fruit juice, etc., in the pharmaceutical industry can be used for ointment Wait.

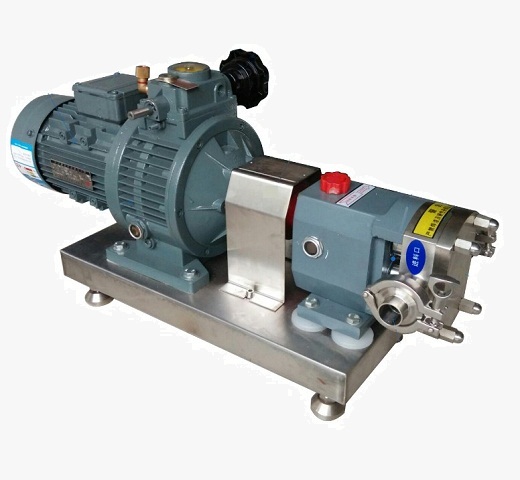

Emulsifying Machine in the use of the process is mainly through the engine to link the quality of the head of the high-speed rotation, the process of operation of the Emulsifying Machine on the material for effective cutting, impact and dispersion, so that the material will become more delicate and effective To promote oil and water.

1, after the completion of production, the Emulsifying Machine must be clean and clean, so that both to maintain the efficiency of the rotor can play a role in protecting the emulsifier seal. If necessary, in the vicinity of the design and installation of a set of cleaning cycle device.

2, the Emulsifying Machine to confirm the machine to seal the cooling water, start the motor, and repeatedly asked the motor steering should be consistent with the steering wheel logo to work, is strictly prohibited reverse!

3, the operation found in the shaft there is liquid leakage phenomenon, you must adjust the pressure after the shutdown machine.

4, according to the user's use of different media, import and export filters must be regularly cleaned in order to avoid the amount of feed to reduce the impact of production efficiency. Into the work chamber material must be fluid, do not allow dry powder, clumps of material directly into the machine, otherwise, will cause boring machine and damage the emulsifier.

5, is strictly prohibited metal scraps or hard to break the debris into the emulsifier working chamber, so as to avoid the work of the stator, rotor and equipment, the devastating damage.

6, in the Emulsifying Machine machine before the development of the corresponding safety production procedures to ensure the safety of operators and equipment. In the electrical control system users to set the security protection system, and a good and reliable electrical motor grounding device.

7, the Emulsifying Machine to be regularly checked, the rotor, found that wear is too large, should promptly replace the corresponding parts to ensure dispersion, emulsifying effect.

8, the use of emulsifiers, the liquid material must be continuous input or maintain a certain amount in the container. Should avoid the air machine running, so as not to cause the material in the work of high temperature or crystal curing equipment damage!

9, the Emulsifying Machine in the course of the operation of any abnormal sound or other failure, it should immediately stop checking, to be troubleshooting and then run. After the shutdown should be working inside the cavity, the rotor clean.

Guangzhou Jinfeng Light Industry Machinery Co. ,Ltd is a manufacturer that produces cosmetic ,pharmaceutical,chemical and dairy product equipment. The main products are vacuum homogeneous emulsifying machines ,reverse osmosis water treatment machines ,automatic and semi-automatic filling machine and all kinds of stainless steel tanks,all of which are of reliable quality and good effect.E-Mail: sales@jfqgjx.com / joyce@jfqgjx.com

“Recommend”

【editor】:JinfengCopyright:http://www.china-jfmachinery.comReproduced please indicate the source